-

Call Us On

+91 9033306316 -

Mail Us

mkt@gajroll.com

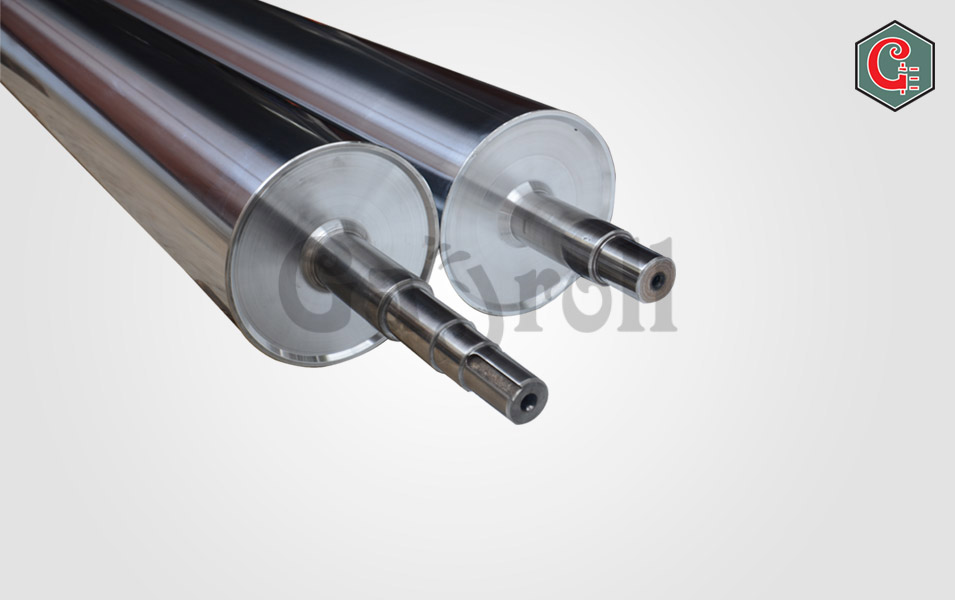

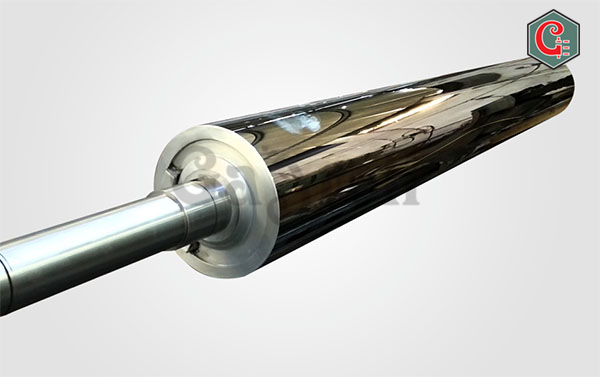

We are offering our clients with a superior range of hard chrome plating rollers that are known for their efficient performance and resistance against corrosion. The uses of superior engineered rollers are manufactured using finest grade materials and makes them function more smoothly and quietly.

The range of deposit thickness on our hard chrome varies from ‘flash’ plating of around 7.5 to 25 microns to heavy hard chrome deposits of up to 350 microns and hardness of up to 65 HRC. These heavier hard chrome deposits usually require grinding and polishing after plating to maintain tolerances and surface finish profile.

| Ra micro-meter ( μm) | ISO Grade Numbers | Roughness Grade Symbol | Application |

| 50 | N12 | ∇ | Rough, low grade surface resulting from torch or saw cutting ,chipping or rough forging. Machine operations are not required because appearance is not objectionable. |

| 25 | N11 | Rough, low grade surface resulting from heavy cuts and coarse feeds in milling,turning,shaping,boring and disc grinding .It is suitable for clearance area on machinery, jigs and fixtures. | |

| 12.5 | N10 | ||

| 6.3 | N9 | ∇∇ | Coarse production surface for unimportant clearance and cleanup operation, resulting from coarse surface grind , rough file, disc grind, rapid feeds in turning and grinding etc. where tool marks are not objectionable. |

| 3.2 | N8 | The roughest surface recommended for parts subject to loads,vibration,and high stress. It is also permitted for bearing surface when motion is slow and load light or infrequent. | |

| 1.6 | N7 | A good machine finish produced under controlled condition using relatively high speed and fine feeds to take light cuts with sharp cutting. It may be specified for close fits and used for all stressed parts, except fast rotating shafts, axles and parts subject to severe vibration or extreme tension. | |

| 0.8 | N6 | ∇∇∇ | A high -grade machine finish requiring close control when produced by lathes ,shapers, milling machines, etc. But relatively easy to produce by centerless cylindrical or surface grinder.

A high quality surface produced by fine cylindrical grinding, emery buffing,cosrse honing or lapping. It is specified where smoothness is of primary importance. |

| 0.4 | N5 | A fine surface produced by honing, lapping or buffing. It is specified where packings and rings must slid across the direction of surface grain. It may be also required in precision gauges and instrument work, or sensitive value surface, or rapidly rotating shafts and on bearing where lubrication is not dependable. | |

| 0.2 | N4 | ||

| 0.1 | N3 | ∇∇∇∇ | A costly refined surface produced by honing ,lapping and buffing. It is specified only when design requirements make it mandatory. |

| 0.05 | N2 |